The wire solution for dishwashers

The Schnee-Gruppe is one of the world's leading dishwasher rack manufacturers for residential and commercial dishwashers.

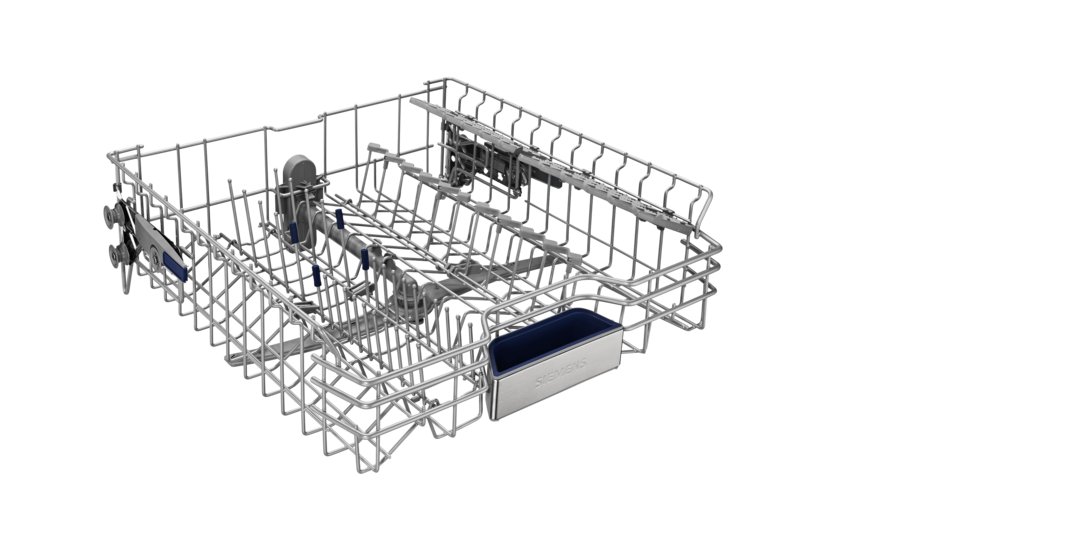

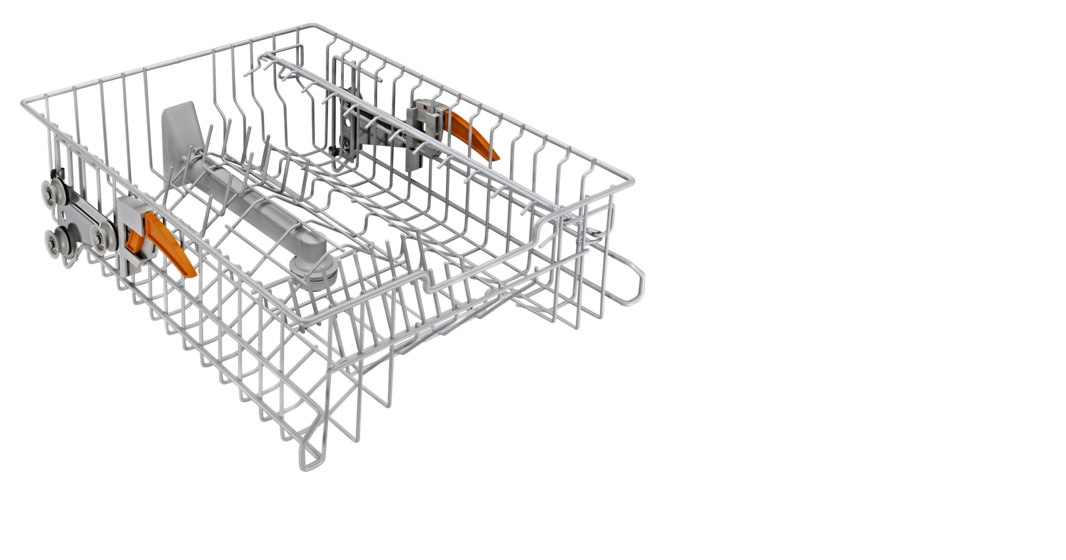

Wet Residential

Wire rack for dishwashers

Plate holder with integrally moulded spherical heads

- for better drying through guaranteed point contact

- for fixing attachments

- tolerance guarantee +/- 0.20 mm including PA coating

Rack height adjustment fully assembled in the in-line process including 100% test for completeness and function

Half-frame technique for creating variations

Plate holder folds down

Rack handle with insert is pre-assembled and completely assembled on the rack, including 100% in-line test

The grip is of stainless steel, brushed, with stamping, laser-etched or made specifically for the customer and type

8 rack rollers assembled in the in-line process including 100% test for completeness and function

Variable dishwasher rack production, 55 cm or 60 cm wide - thanks to an ingenious, proprietary manufacturing technology with intelligent tool changing system

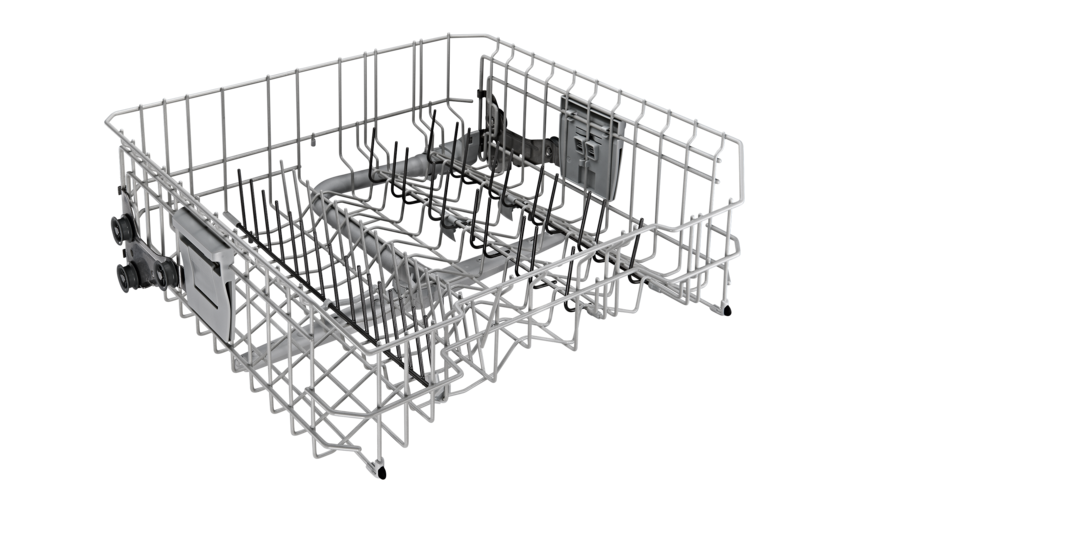

Complete assembly: Water hydraulics and spray arm mounted ready for installation

Rack height adjustment fully assembled in the in-line process including 100% test for completeness and function

Guide rollers fully assembled in the in-line process including 100% test for completeness and function

Mounted ready for installation

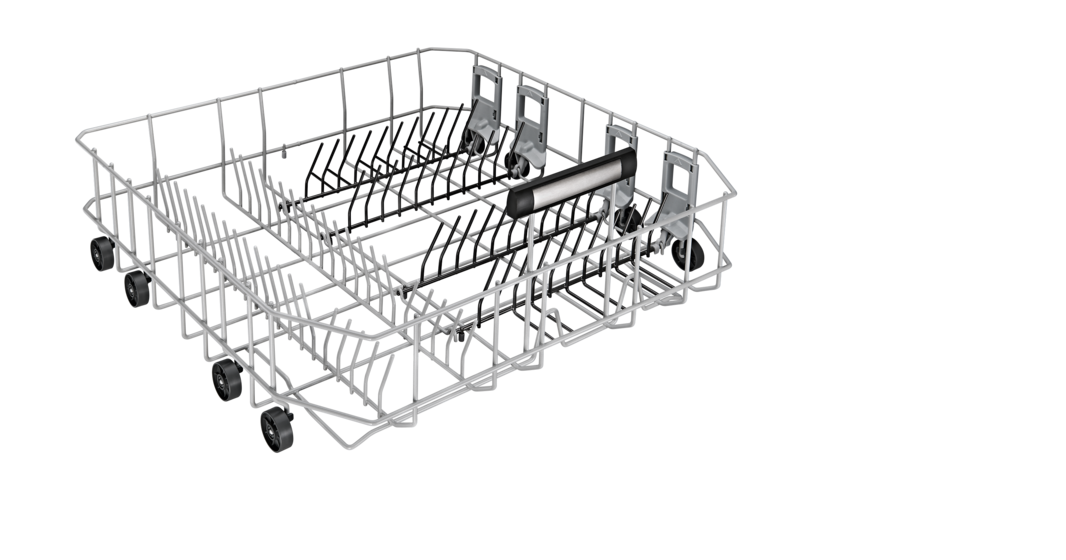

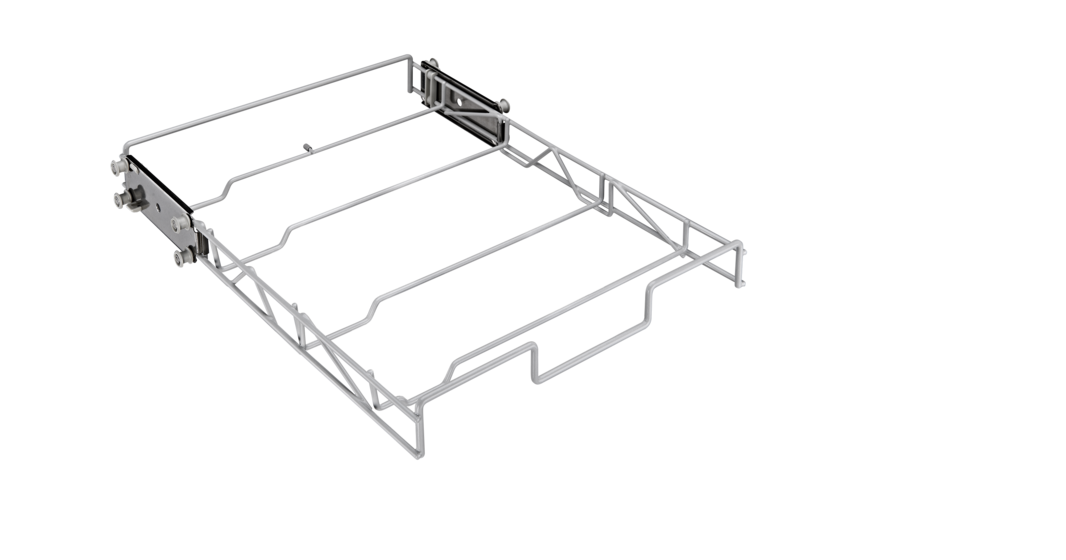

Wire rack for dishwashers

Height-control collision guard integrated rack handle with 1.4301 brushed insert pre-assembled and mounted on the cutlery frame

With folding function in the front

Rear of the rack area with changeable inserts

8 rack rollers assembled in the in-line process including 100% test for completeness and function

Rack height adjustment fully assembled in the in-line process including 100% test for completeness and function

Water hydraulics and spray arm mounted ready for installation

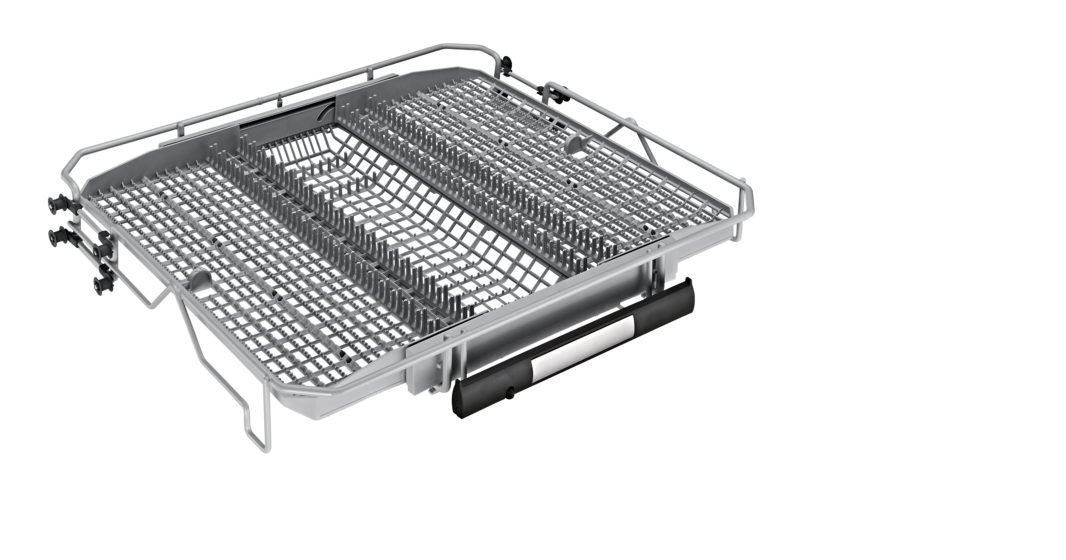

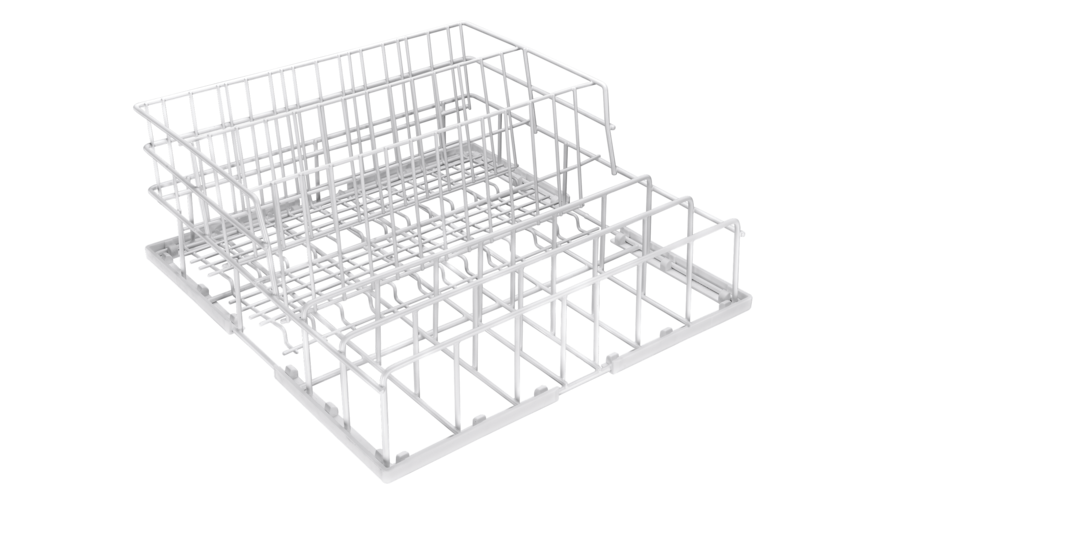

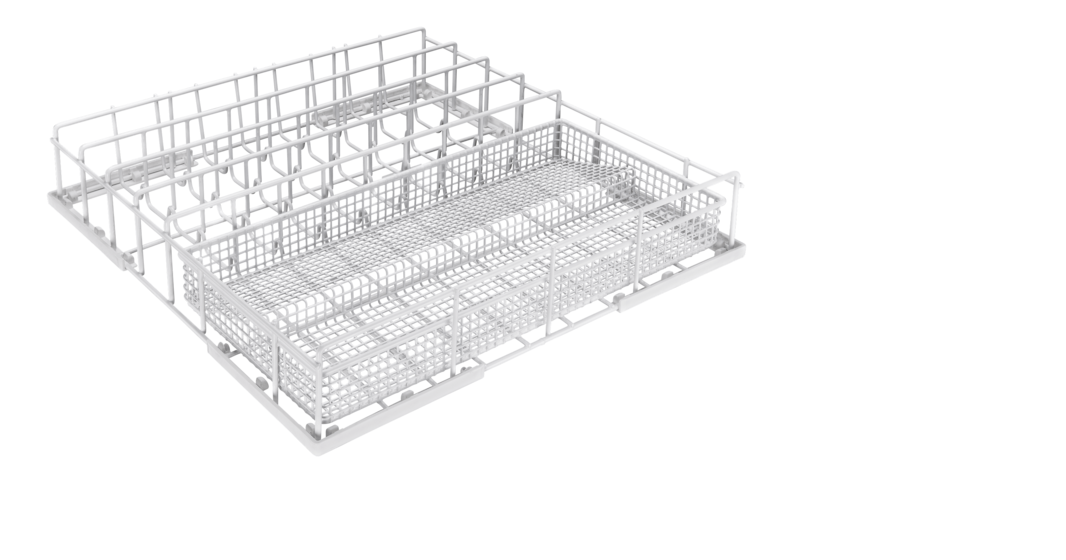

Cup rack made of wire

Wire-frame construction of PA-coated St 37 as a sub-assembly for final assembly by the customer

Documented 100% in-line testing

6 folding plate holder racks with locking lever and integrally moulded spherical head for mounting customer components

Glass holder brackets as an assembly or pre-assembled in various designs according to customer needs

Folding rack and support plate mounted manually

8 rack rollers assembled in the in-line process including 100% test for completeness and function